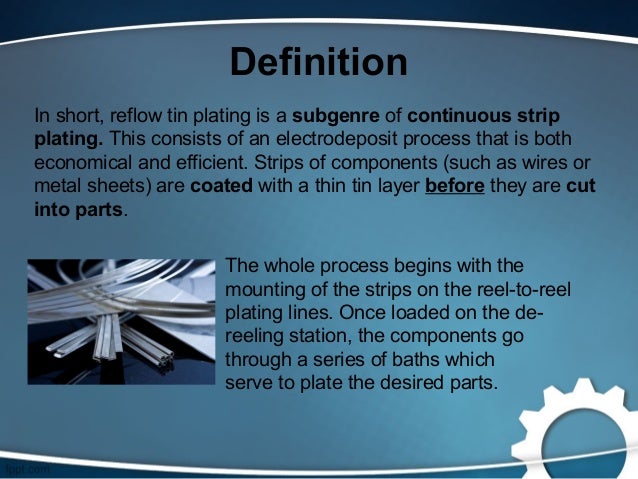

These steps are vital in ensuring that both the chips and the PCB are not exposed to excessive temperatures which will cause problems that aren’t noticed until much later in the manufacturing process when it might be too late to rectify. It’s a very efficient way of attaching components to a PCB, but there are many variables that require complex calculation including: line speed oven size thickness of PCB and number of layers. The entire unit is heated quickly so that the solder will melt and form acceptable solder joints between the components and the board. Reflow is a soldering process during which components are placed onto the PCB with a thin layer of solder paste between them and the board.

You may wonder why this is an issue… how bad can it be if a component takes on a little moisture and how could this affect the functionality of the device? In fact, before we even consider the effect on how an exposed device functions inside a finished product, we need to step back and look at the serious problems absorbed moisture can cause during a process called reflow in printed circuit board assembly (PCBA). Why do Components need to be baked?Īll integrated circuits (ICs) are subject to moisture ingress if left in an ambient environment. If these components have been stored in an ambient environment, it can result in outcomes very detrimental to the manufacturing process. In addition, the conveyor speed is programmable at 400-1800 mm (16"-71") per minute to accommodate your processing requirements.Īdditional pin conveyor options include automatic width adjustment based on parameter settings for specific reflow programs and a center support system to prevent board warpage for processing of larger PCBs at higher lead-free temperatures.In the great chip shortage of 2021, many electronics manufacturers have had no option but to use stock they’ve held in storage with older date codes or source their components from channels outside of their regular supply chain, not knowing what condition they have been stored in. Standard pin conveyor features for the 8-zone model include advanced automatic chain lubrication and motorized width adjustment. With double-sided and inline processing capabilities, this belt is ideal for fast changeovers.Įach of our components is composed of high-quality, high-strength stainless steel and built to maintain dimensional tolerances at the high temperatures required by lead-free processing, eliminating the possibility of jams or dropped PCB assemblies. This system can handle PCBs up to 430 mm (17") installed over a 570 mm (22") stainless-steel mesh belt. Our 8-zone oven can meet virtually any product specification or production requirement with its standard adjustable-rail, pin-type conveyor.

Define reflow software#

Simply choose your solder past formula and process window, specify your product's physical characteristics, and our software will provide you with zone temperature and belt speed settings for the job. KIC Auto Focus Profile Prediction software offers you complete control over zone temperatures and belt speed settings for optimal temperature gradients, energy efficiency, or speed of production.

Define reflow series#

Each oven comes with 3 built-in inputs standard for communication with the CR Series control software. If you're looking for accurate, real-time temperature profiling to ensure the reflow process matches your solder paste manufacturer's specifications, we offer optional thermocouple installations at critical locations on the PCB.

This diffuser design provides our clients with low-velocity, low-turbulence air flow that prevents component shifts or disturbances. With the addition of the high-speed blower installed adjacent to each heat source for maximum convection, you're guaranteed a ΔT of ☒☌ across the PCB assembly. The CR8000's heating zone temperature controllers permit precise temperature profiling with an accuracy of ☑☌. Independent Upper and Lower PID Temperature Controls for Each Heating Zone

0 kommentar(er)

0 kommentar(er)